Today there are 3 smelters in 3 continents where ALPSYS V15 is in operation, totalising 1320 cells under management.

Alpsys V15 is not only a new IHM version. New process control functions are enclosed allowing additional features for a more competitive cell control.

This new version is also ready by design to embed industry 4.0 concept such as:

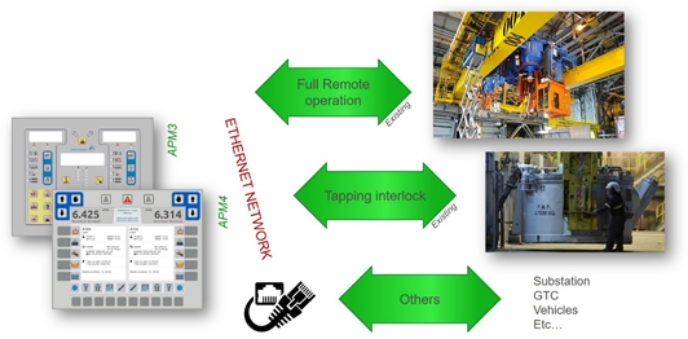

Extended communication with external equipment’s to allow operator to launch operation procedure on cell directly from their dedicated control panel such as Crane PLC. The APM3 potmicro, and the new next generation APM4 are designed with an Ethernet communication (as compared to a serial communication on APM1 and 2). It is now possible to have more complex communications with other equipment’s.

- As an example: today, operations could be completely managed from the PTA HMI, with no need for the operator to go to the potmicro. All actions are done from the PTA HMI and the required cell information is displayed by the PTA.

- Another example is the tapping interlock, which prevent the PTA from launching the metal siphoning if the potmicro is not ready for it. This effectively remove one of the major risks in a potline.

The APM4 comes with a large graphic screen that displays more information and graphics (1 min graph, 1s graph…).

In any situation, the operator will get more information right on the shopfloor. Better information on the cell, means a better diagnostic from the operator. The end result being a quicker and better treatment of the situtation.

Smart measurement to improve data quality allowing users to make measurement on cell. The APM4 / Ethernet environment opens the way to projects like the SmartPOT which is designed to improve data quality.

- It can be validated → a temperature taken just after a big anode effect may be considered invalid.

- It can be adjusted → a temperature taken after an anode change can be corrected depending on the anode position, and time since the anode change.

- It can be enhanced → a temperature is completed by context information: cell instability, cell age, etc… all information that is relevant to interpret the measure

HashTag to give flexibility for Reduction Staff.

Having a lot of data is good, but things may change quickly in a potline.

To face a new situation, flexibility is important. Flexibility is to allow the potline staff to quickly adapt its practices to a new situation.

#HashTag tool allows the potline staff to create new data on its own. New KPI can be created just by typing in a calculation formula in a screen. It is very similar to what you do in Excel. The new data is automatically calculated. It can be calculated every minute, every hour, every day. This data can then be used for many purposes: selecting abnormal cells, as a process control KPI, in dashboards, to automatically change parameters, etc…

Mobility by allowing the use of mobile device.

In order to take a quick decision, and the right decision, wherever you are, you need the right information on the spot.

Mobility will provide access to Level 2 screens from mobile device: tablets or smartphones. We are not talking just about having access to Level 2 screens on smartphones. The screens are Full HD and need to be adapted for smaller screens.